The disc separator is an advanced centrifugal separation equipment with the characteristics of high efficiency, large output, small footprint, and high automation. Its separation factor is usually greater than 3500, and the drum speed can reach up to 4000-12000r/min. Commonly used to handle highly dispersed liquid-liquid two-phase emulsions and liquid-solid two-phase suspensions composed of small particles in high viscosity liquid phases, which are difficult to separate.

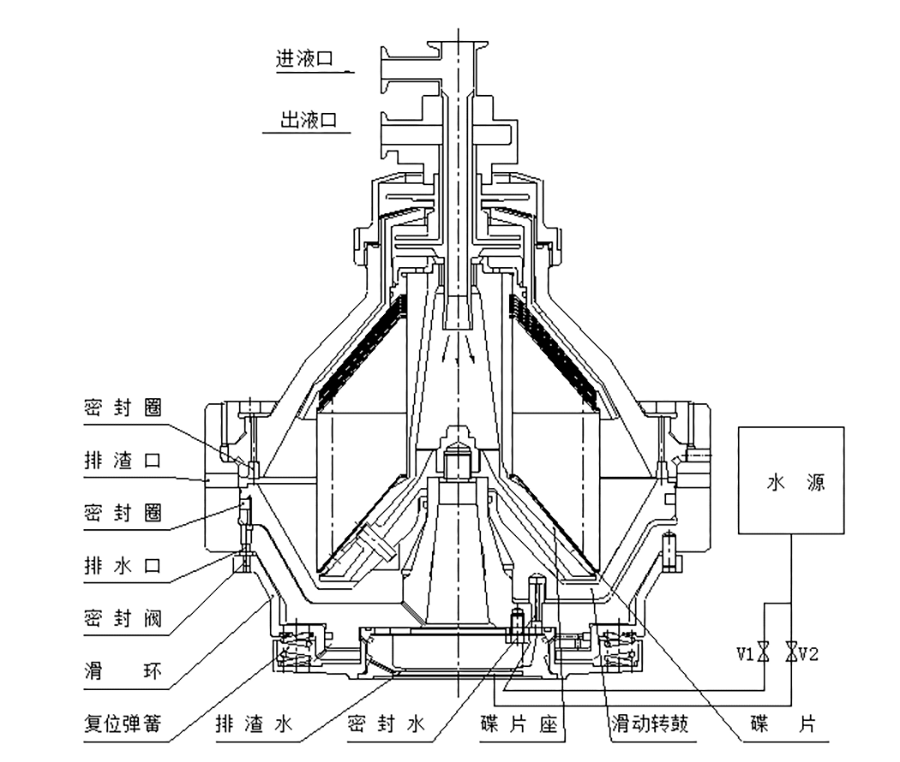

The disc separator is composed of multiple main components, including a drum, transmission system, feeding and discharging device, base, casing, and control system. The vertical shaft is a flexible shaft structure, and the drum is installed at the upper end of the vertical shaft. The transmission system is composed of a centrifugal clutch, a horizontal shaft, a spiral gear pair, and a vertical shaft driven by an electric motor, which drives the drum to rotate at high speed. The majority of the casing is cylindrical or conical, with the lower part fixed to the base and the upper part equipped with feeding and discharging devices. Inside the casing is a high-speed rotating drum component, which is equipped with a disc holder and a disc bundle composed of several discs. The upper part of the drum is equipped with a collection chamber for collecting clarified liquid and a skimming pump. By using a high-speed rotating drum and the correct control system, the disc separator can efficiently separate various difficult to separate liquid-liquid and liquid-solid two-phase mixtures. In the pharmaceutical production process, disc separators can achieve the separation and purification of antibiotics, blood products, biological products, etc., improving product quality and production efficiency. At the same time, due to its high level of automation and easy operation, disc separators have become one of the indispensable and important equipment in modern pharmaceutical production. The disc separator is widely used in pharmaceutical production, and its separation effect and production capacity have been unanimously recognized in the industry.

Usage: Disc separators are widely used in industries such as medicine, chemical industry, petroleum, transportation, food, light industry, and bioengineering, especially in the pharmaceutical industry. They are widely used in antibiotics, blood products, biological products, traditional Chinese medicine extraction, starch, marine oil, and power plant industries.